Buying A Used Scissor Lift: 4 Questions You Should Ask

Buying a new scissor lift or renting a lift for an extended period of time can be costly. Long lead times have also become an issue on many models. Buying a used scissor lift is a cost-effective alternative to renting or buying new. Not only will it save you money, but you can end up with a lift that’s ideal for your needs.

Make sure to ask the seller the following 4 questions to help ensure that you’re getting a good lift that has been properly maintained:

1. How has this scissor lift been maintained?

One benefit of buying a used lift from a rental yard, is that it’s pretty easy to find out if the lift has been properly maintained.

When asked how a piece of equipment is maintained, the seller should tell you that quarterly and annual inspections have been conducted. In addition, rental yards will inspect their machines before each rental to ensure their lifts are in good condition while on job sites.

Most companies do not provide years of service records because it can take a great deal of time to pull and reproduce sometimes hundreds of pages of records. Instead, request the most recent annual inspection report for the most up-to-date equipment details.

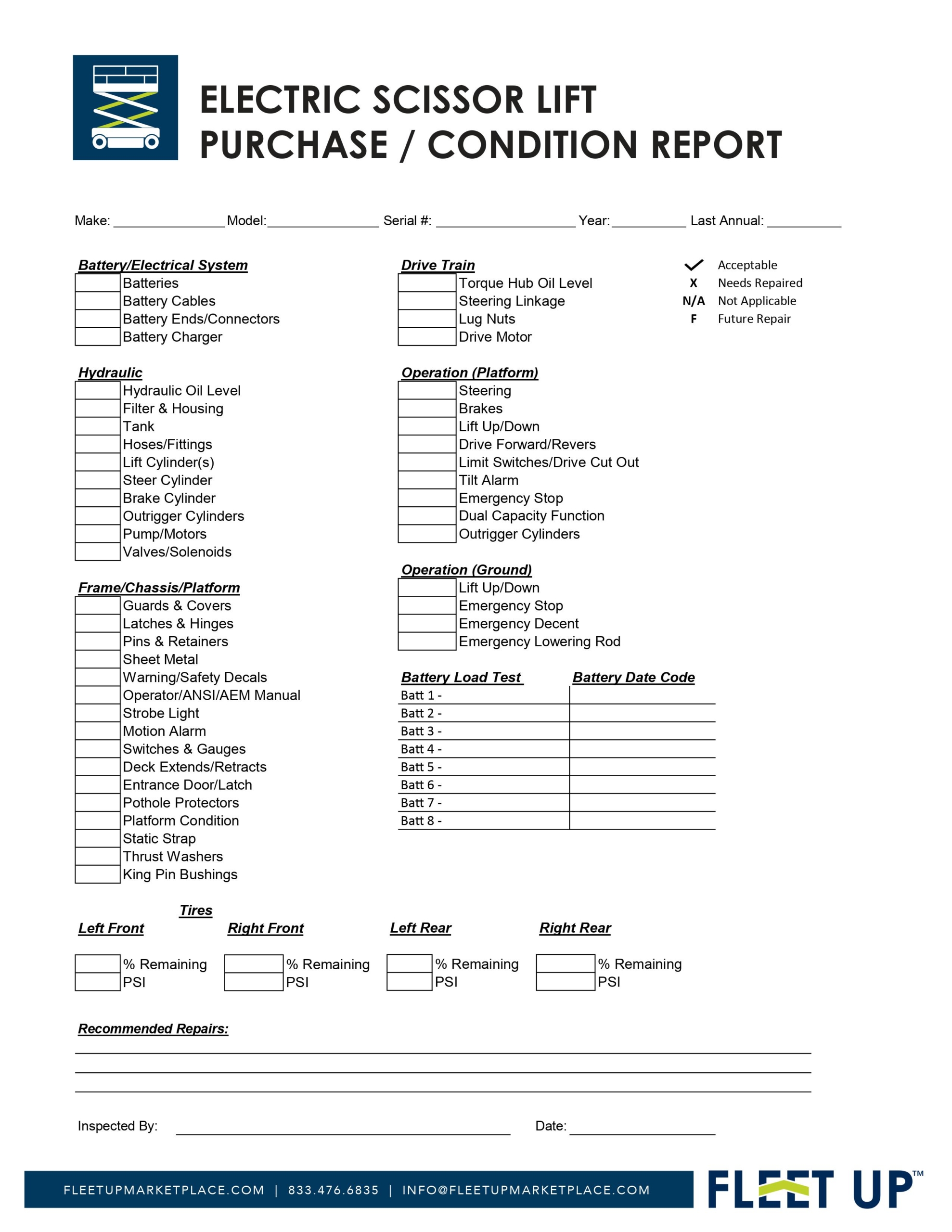

FREE DOWNLOAD

Scissor Lift Inspection Report

This inspection report will help you assess the condition of the lift

2. What condition are the tires in?

Tires can be expensive to replace. While some wear and tear on the tires is fine, make sure the lift does not vibrate when moving as a result of the tires’ condition. Also check for any structural damage like flat spots, cracks, or bubbles in the sidewalls.

3. When were the batteries replaced, and how do you maintain them?

Batteries need to be replaced every few years; however, properly maintained batteries will last longer than batteries that aren’t maintained regularly. Batteries should be maintained by:

- Charging them fully

- Adding distilled water as needed

- Watching for and cleaning any visible debris or corrosion

- Measuring and retaining hydrometer readings

- Verifying all connections are tight and secure

Ask the seller to send you photos of the batteries. Look for debris or any corrosion as a sign that it has not been properly maintained.

Note: If you’re buying a lift that’s priced under market value, it’s likely that you’ll need to replace the battery and perform additional repairs and maintenance.

4. Are there any leaks that cause puddling?

Minor leaks or “oil saturation” is not unusual on scissor lifts. However, any leaks that cause puddling should be acknowledged and addressed. Seals, control valves, cylinders, hydraulic hoses & filters, and loose nuts can all cause leaks.

Major leaks can be expensive and dangerous. For example, oil leaks can cause overheating, the oil can catch on fire, they can be an indicator of a bigger problem, and they can cause costly downtime.

When you are looking at a scissor lift for sale, the answers to the questions above will help you make an informed decision before you buy. Be sure to download the Used Scissor Lift Inspection Report to ensure the machine you buy is right for you.

If you have questions, don’t hesitate to contact us. We’re here to help you make informed decisions before buying used construction equipment, and to help you find the right machine.

FleetNow Equipment Experts: info@fleetupmarketplace.com – or – 1.216-973-5124